fredag 12. november 2010

Robots in Architecture

We recently presented our paper "A New Parametric Design Tool for Robot Milling" at theACADIA 2010 conference in New York. We had a great time there and thank all of our friends who got up on a Sunday morning - after the big party, no less - to follow our presentation.

In our paper we show approaches on how to integrate the robot not just in the parametric model, but in the design process itself. The example above is a screenshot (with added captions) directly out of Grasshopper, showing the initially created curves, the resulting modules and finally the stacked wall - side by side with a preview of the toolpaths, including the possibility to simulate the end-effector movements and extract KRL (KUKA Robot Language) code. It's all running very fluently, allowing you to quickly iterate alternatives, both in respect to design and production. Finally, due to the KRL code generation, you can also rapidly output KRL files for mass customization, circumventing the lengthy CAD-CAM-Postprocessor workflow.

http://robotsinarchitecture.blogspot.com/

ACADIA 2010 | A New Parametric Design Tool for Robot Milling from Johannes Braumann on Vimeo.

fredag 5. november 2010

onsdag 3. november 2010

Fabricate

FABRICATE is an International Peer Reviewed Conference with supporting publication and exhibition to be held at The Building Centre in London from 15-16 April 2011. Discussing the progressive integration of digital design with manufacturing processes, and its impact on design and making in the 21st century, FABRICATE will bring together pioneers in design and making within architecture, construction, engineering, manufacturing, materials technology and computation. Discussion on key themes will include: how digital fabrication technologies are enabling new creative and construction opportunities, the difficult gap that exists between digital modeling and its realization, material performance and manipulation, off-site and on-site construction, interdisciplinary education, economic and sustainable contexts.

http://www.fabricate2011.org/

Francois Roche / Interviewed by Jeffrey Inaba and Benedict Clouette

http://www.new-territories.com/columbia%20interview.htm

torsdag 30. september 2010

Radiolara pavilion - the first printed building

In a small shed on an industrial park near Pisa is a machine that can print buildings. The machine itself looks like a prototype for the automotive industry. Four columns independently support a frame with a single armature on it. Driven by CAD software installed on a dust-covered computer terminal, the armature moves just millimetres above a pile of sand, expressing a magnesium-based solution from hundreds of nozzles on its lower side. It makes four passes. The layer dries and Enrico Dini recalibrates the armature frame. The system deposits the sand and then inorganic binding ink. The exercise is repeated. The millennia-long process of laying down sedimentary rock is accelerated into a day. A building emerges. This machine could be used to construct anything. Dini wants to build a cathedral with it. Or houses on the moon.

http://www.d-shape.com

http://www.blueprintmagazine.co.uk/index.php/architecture/the-worlds-first-printed-building/

onsdag 29. september 2010

CITA (Center for It og Arkitektur)

CITA is an innovative research environment exploring the emergent intersections between architecture and digital technologies. Identifying core research questions into how space and technology can be probed, CITA seeks to investigate how the current forming of a digital culture impacts on architectural thinking and practice.

CITA examines how architecture is influenced by new digital design- and production tools as well as the digital practices that are informing our societies culturally, socially and technologically. Using design and practice based research methods; the aim is to explore the conceptualisation, design and realisation of working prototypes. CITA consolidates new collaborations with interdisciplinary partners from the fields of computer graphics, human computer interaction, robotics, artificial intelligence as well as the practice based fields of furniture design, fashion and textiles, industrial design, film, dance and interactive arts.

By examining technology transfers between high-innovative industries, that stand on front edge in the development of new digitalised designs- and production tools, it's our goal to create synergy between the subject's contemporary reality and its future perspective.

http://cita.karch.dk/

onsdag 22. september 2010

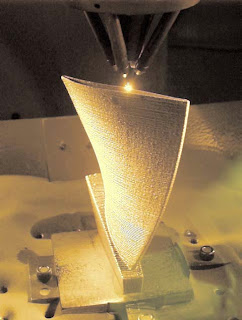

Laser Engineered Net Shaping

Sandia National Laboratories has developed a new technology to fabricate three-dimensional metallic components directly from CAD solid models. This process, called Laser Engineered Net ShapingT (LENS®), exhibits enormous potential to revolutionize the way in which metal parts, such as complex prototypes, tooling, and small-lot production items, are produced.

tirsdag 21. september 2010

Fused Deposition Modeling

Fused deposition modeling (FDM) is an additive manufacturing technology commonly used for modeling, prototyping, and production applications. The technology was developed by S. Scott Crump in the late 1980s and was commercialized in 1990.

FDM works on an "additive" principle by laying down material in layers. A plastic filament or metal wire is unwound from a coil and supplies material to anextrusion nozzle which can turn on and off the flow. The nozzle is heated to melt the material and can be moved in both horizontal and vertical directions by a numerically controlled mechanism, directly controlled by a computer-aided manufacturing (CAM) software package. The model or part is produced by extruding small beads of thermoplastic material to form layers as the material hardens immediately after extrusion from the nozzle.

Several materials are available with different trade-offs between strength and temperature properties. As well as acrylonitrile butadiene styrene (ABS) polymer, polycarbonates, polycaprolactone, polyphenylsulfones and waxes. A "water-soluble" material can be used for making temporary supports while manufacturing is in progress, this soluble support material is quickly dissolved with specialized mechanical agitation equipment utilizing a precisely heatedsodium hydroxide solution.

http://en.wikipedia.org/wiki/Fused_deposition_modeling

http://en.wikipedia.org/wiki/Fused_deposition_modeling

RhinoAssembly

RhinoAssembly, the first Driving Dimensions plug-in for Rhinoceros, is a powerful tool for assembly design and kinematic simulation with capabilities of mainstream mechanical CAD packages. With RhinoAssembly you can easily position your rigid 3D parts with respect to each other by specifying assembly constraints (fixation, concentricity, coincidence, parallelism, perpendicularity, tangency, rigid sets) and driving dimensions (distance and angle) between their faces and edges.

http://drivingdimensions.com/Rhino/

mandag 20. september 2010

Computation Group, MIT

|

| Yuchen Liu's SMArchS thesis at MIT |

The Computation discipline group of MIT's Department Architecture inquires into methods of architectural design, and challenges the limits of current technology, as well as conventional design teaching and practice. It focuses on the development of innovative computational tools, design processes and theories, and applying these in creative, socially meaningful responses to challenging design problems. Faculty, research staff, and students work in diverse and mutually supportive areas including:

- visualization, video and animation

- rapid prototyping and CAD/CAM technologies

- shape representation and shape synthesis

- building information modeling (BIM)

- generative and parametric design

- critical studies of digital and information technologies

- software/hardware development of advanced tools for spatial design

- application of design technology to real world design problems

THEVERYMANY

MARC FORNES (registered Architect DPLG) is the founder and principal of THEVERYMANY - www.theverymany.net - a design studio and collaborative research forum engaging the field of architecture via what he qualifies as “Explicit and Encoded protocols”.

http://theverymany.com/

søndag 19. september 2010

Gramazio & Kohler

"In our research we examine the changes in architectural production requirements that result from introducing digital manufacturing techniques. Our special interest lies in combining data and material and the resulting implications this has on the architectural design. The possibility of directly fabricating building components described on the computer expands not only the spectrum of possibilities for construction, but, by the direct implementation of material and production logic into the design process, it establishes a unique architectural expression and a new aesthetic."

ISO: Service Robots

Provisional definition of Service Robots

Service robots have no strict internationally accepted definition, which, among other things, delimits them from other types of equipment, in particular the manipulating industrial robot. IFR, however, have adopted a preliminary definition:

A service robot is a robot which operates semi- or fully autonomously to perform services useful to the well-being of humans and equipment, excluding manufacturing operations.

With this definition, manipulating industrial robots could also be regarded as service robots, provided they are installed in non-manufacturing operations. Service robots may or may not be equipped with an arm structure as is the industrial robot. Often, but not always, the service robots are mobile. In some cases, service robots consist of a mobile platform on which one or several arms are attached and controlled in the same mode as the arms of the industrial robot.

Because of their multitude of forms and structures as well as application areas, service robots are not easy to define.

Types of Industrial Robots

Classification by mechanical structure (types of industrial robots):

- Articulated robots

- Cylindrical robots

- Linear robots (including cartesian and gantry robots)

- Parallel robots

- SCARA robots

|

| http://www.ifr.org/industrial-robots/products/ |

ISO: Industrial Robots

Industrial robot as defined by ISO 8373:

An automatically controlled, reprogrammable, multipurpose manipulator programmable in three or more axes, which may be either fixed in place or mobile for use in industrial automation applications.

Reprogrammable: whose programmed motions or auxiliary functions may be changed without physical alterations;

Multipurpose: capable of being adapted to a different application with physical alterations;

Physical alterations: alteration of the mechanical structure or control system except for changes of programming cassettes, ROMs, etc.

Axis: direction used to specify the robot motion in a linear or rotary mode

fredag 17. september 2010

Robotics

Robotics is the engineering science and technology of robots, and their design, manufacture, application, and structural disposition. Robotics is related to electronics, mechanics, and software.http://en.wikipedia.org/wiki/Robotics

Abonner på:

Kommentarer (Atom)